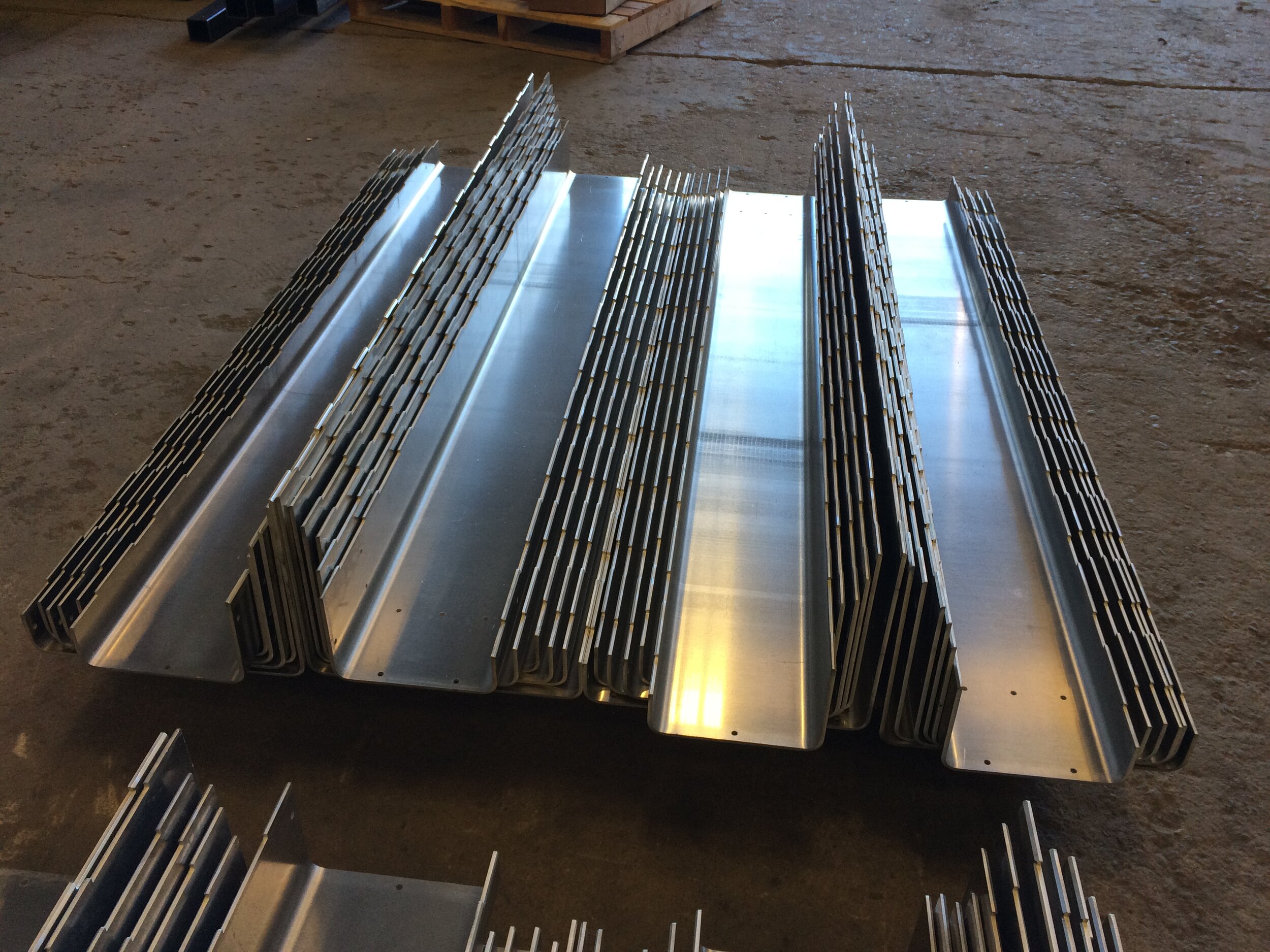

Fabrication

With our CNC laser and plasma table along with our CNC press brakes here at the Vroom fab shop we can cut, brake, and weld whatever our customer needs. If you have an engineered drawing that needs built, or you want us to come up with a solution to a problem we can help.

MATERIAL PROCESSING

Material is efficiently processed in house. Plate is cut using CNC laser, plasma table, or mechanical shear. Shapes, tubes, and beams are cut using various saws.

2016 Mitsubishi EX-S Laser

5’ X 10’ dual pallet table

Capacity to ¾” Steel

5/16” Stainless and Aluminum

Non metallic material such as gaskets, rubber, and wood

2014 Lincoln 400amp plasma

11’ X 22’ water table

2” thick plasma capacity

6” thick oxy acetylene capacity

80 ton piranha

Band saws to 20” diameter capacity

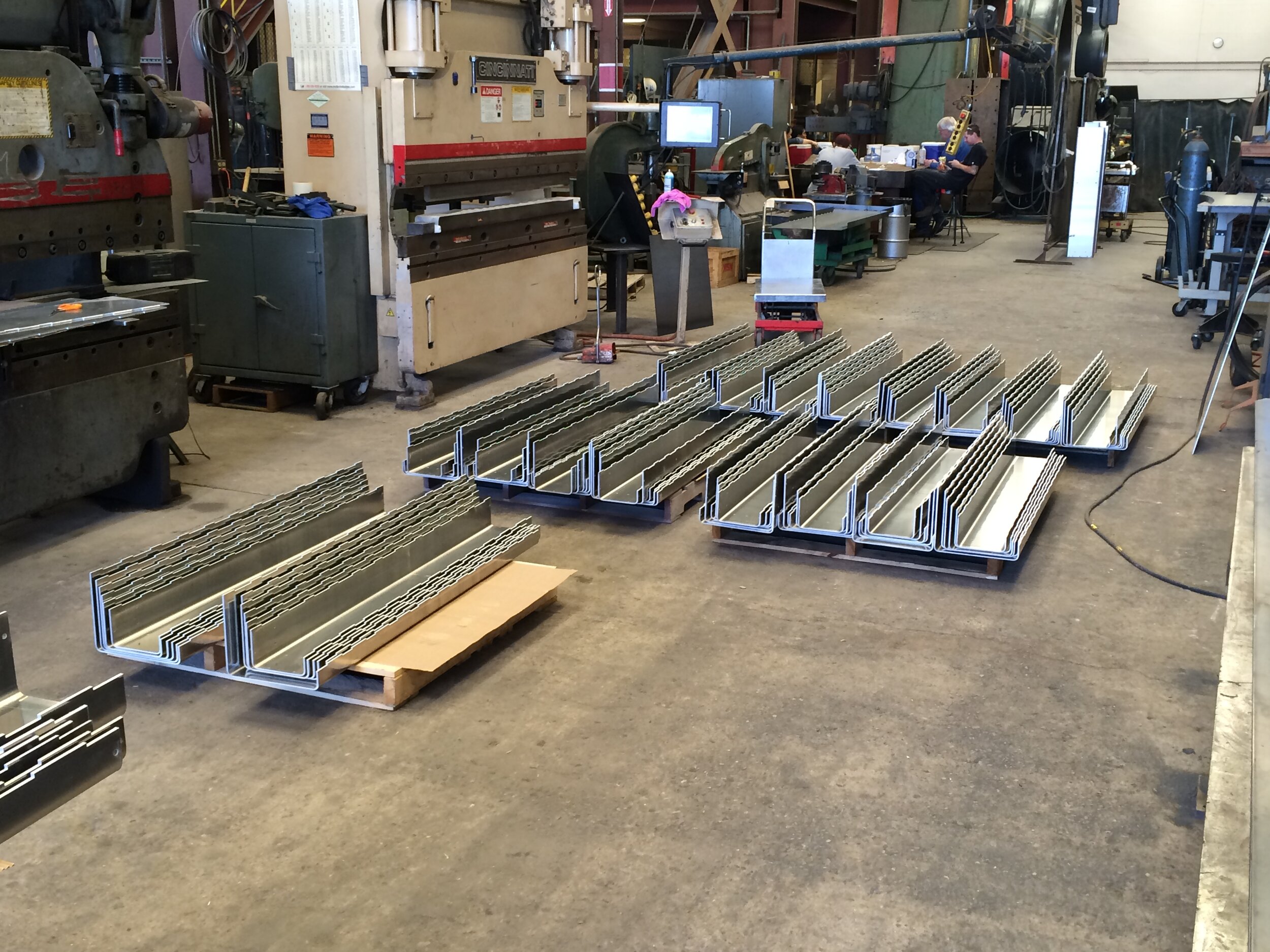

Forming

We have forming equipment to fit most jobs. We have multiple press brakes ranging from 90 to 300 tons. Roll plants that can handle a range of material from thin aluminum up to 1” hardened plate. Numerous other machines allow us to roll shapes such as channel and aluminum square.

Brakes

2007 Cincinnati 90ton ProForm 8’ bed

2018 Cincinnati mechanical CNC brake 14’ bed

300ton hydraulic press brake 20’ bed

Rolls

Bertsch centry 2 roll plant

1” plate 8’ wide

16” ID roll

Buffalo NO.2 shape roll

Aluminum slip roll

Small sheet and part roll

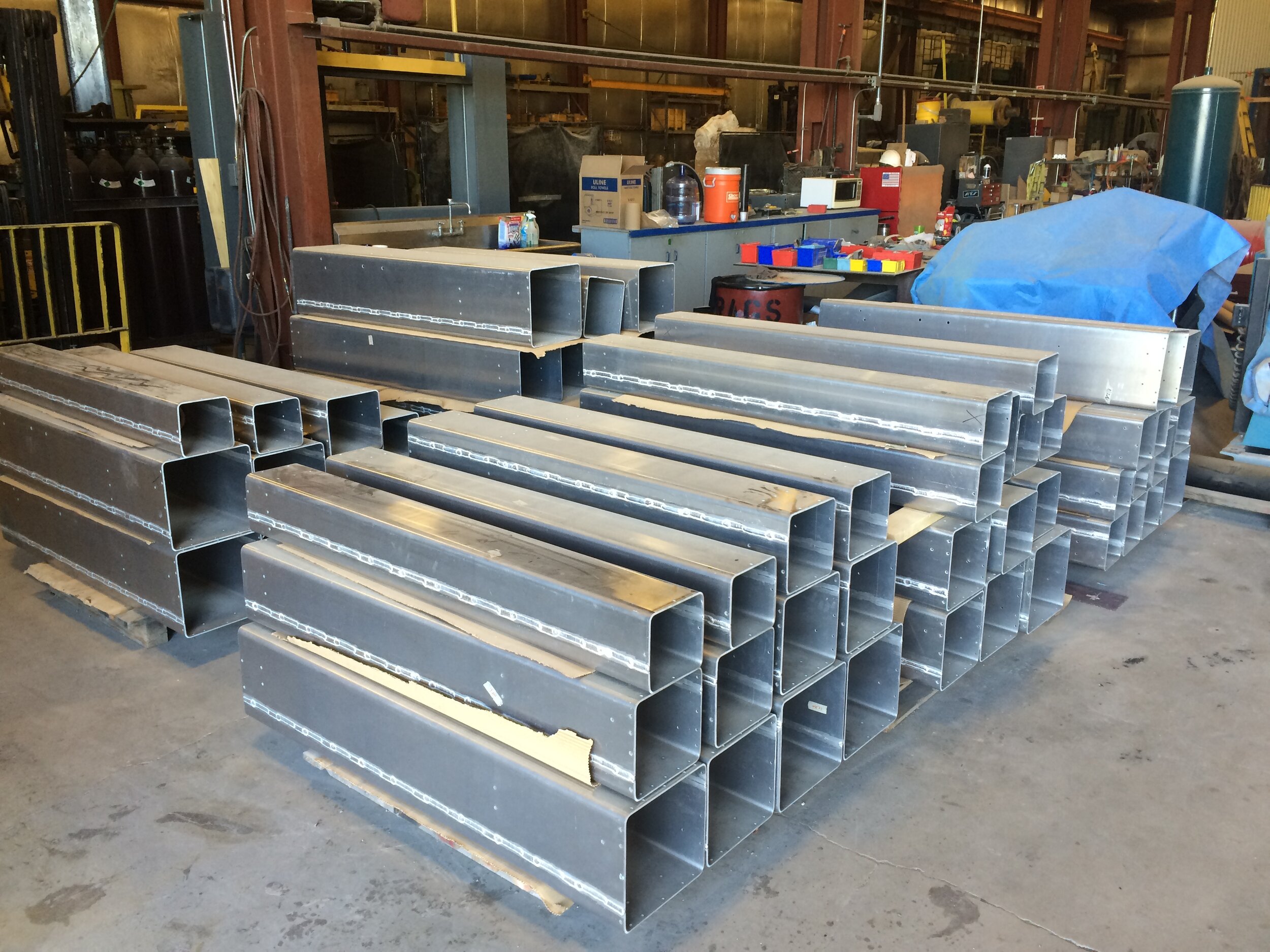

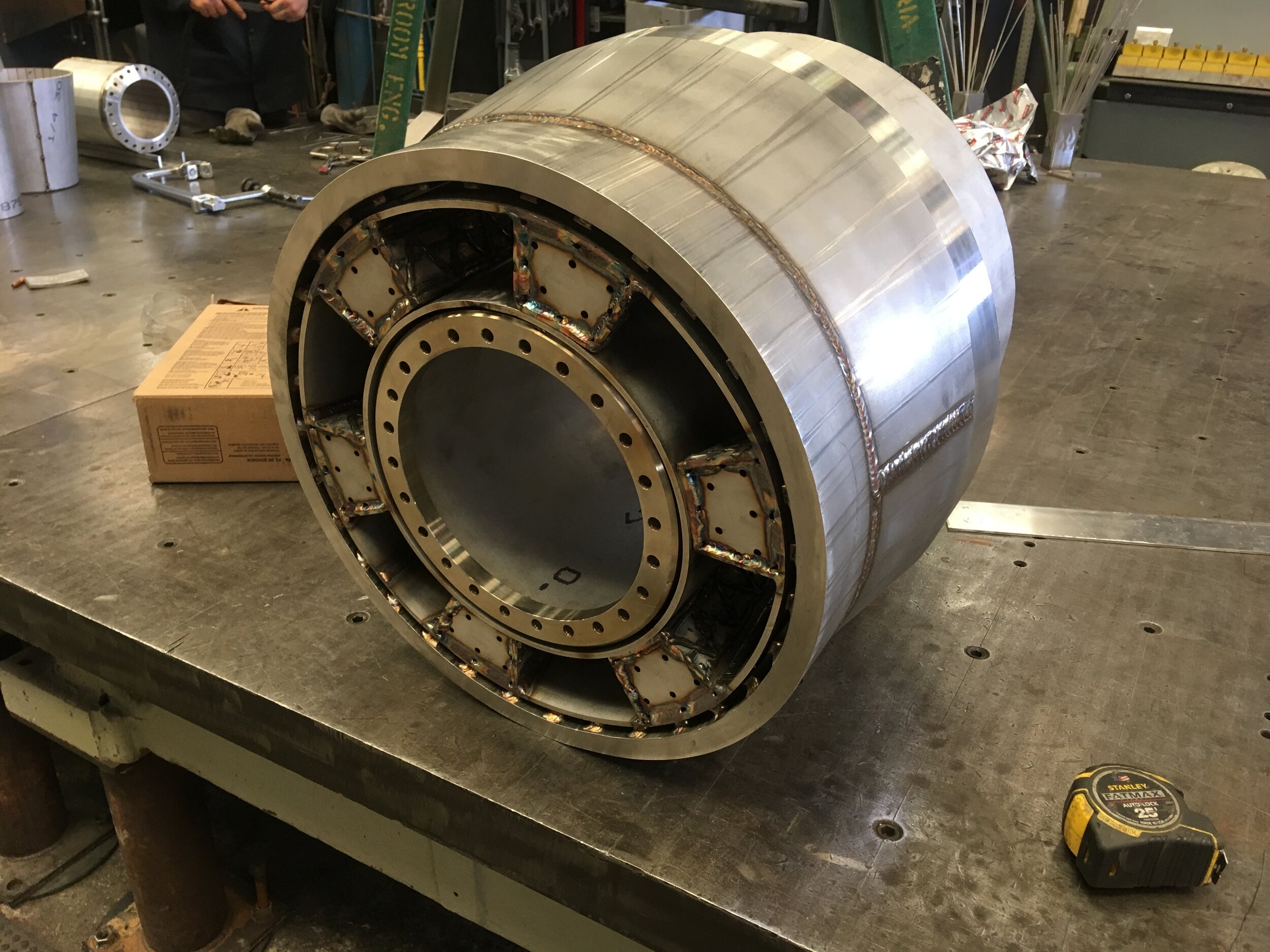

ASSEMBLY/FABRICATION

Vroom’s value-added process of assembly and fabrication means it’s a one-stop shop for our customers. After the material processing and forming are complete, we have a qualified team that can fabricate and assemble your product. Vroom will also test fit the product prior to shipment to ensure perfect assembly at the customer’s final location.

With a 100,000 square foot enclosed facility, 8 bridge cranes (up to 30 ton), and large outside equipment, this allows us to provide service for large and heavy industrial jobs.

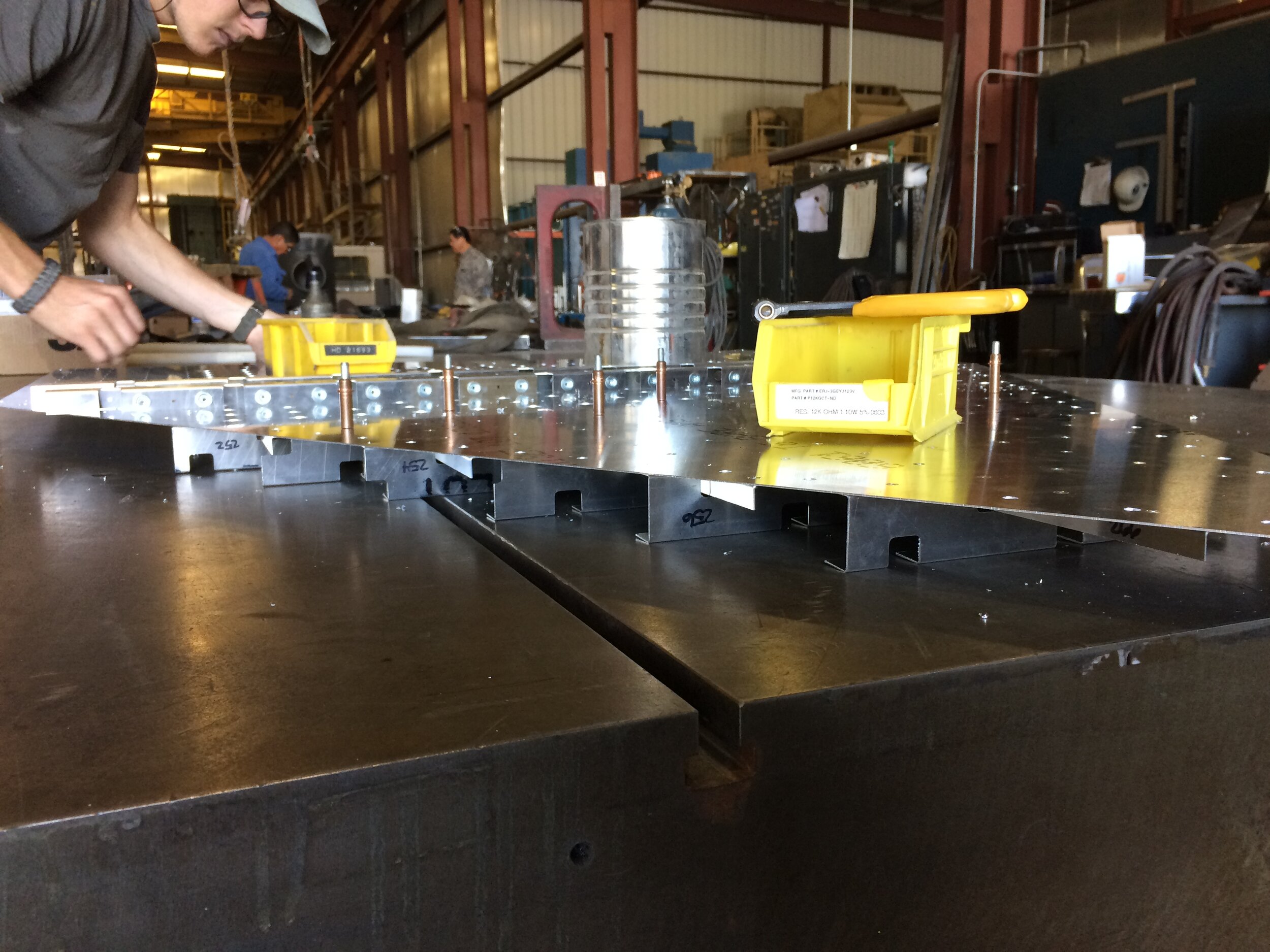

WELDING

Vroom Engineering provides an extensive variety of welding services that range from repairs, modifications, and complete fabrication. Our fabricators focus on delivering quality workmanship in a timely manner each and every job. Our large-bed fabrication combined with robotic welding provides consistent cost-efficient quality and productivity.

2 Stud welders up to 1” diameter

21 Mig welders up to 450 amp

4 Tig welders up to 300 amp

4 Portable Welders up to 450amp

2 (7axis) Robotic welder platforms

Variety of welding positioners